Uses, Benefits and Drawbacks of Fly Ash in Construction

Fly ash can be an expensive replacement for Portland cement in concrete although using it improves strength, segregation, and ease of pumping concrete.

WhatsApp)

WhatsApp)

Fly ash can be an expensive replacement for Portland cement in concrete although using it improves strength, segregation, and ease of pumping concrete.

The processing, characterization, and properties of fly ash based geopolymer concrete 91 advantages over metakaolin in that it is waste resource produced in huge ...

Fly ash is a product which comes from boilers used in the electrical generation process. Thomas Cerullo reports

Optimizing the Use of Fly Ash in Concrete CONCRETE Introduction ... compromising the construction process or the quality of the finished product.

What is Fly ash? Should we use fly ash in concrete? What are the advantages and disadvantages of using fly ash in ... The Full Manufacturing Process; Concrete ...

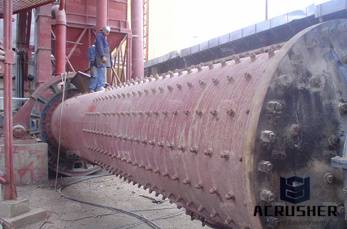

fly ash processing machine . fly ash processing machine. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced ...

Separation Technologies LLC, is a pioneer in the processing of fly ash into a consistent lowcarbon product for the concrete industry. Separation Technologies is the ...

Fly Ash, Slag, Silica Fume, and Natural Pozzolans ... process, the fused material ... Fly ash is used in about 50% of ready mixed concrete (PCA 2000). Class F fly ash ...

» Magazine Articles » Fly ash or GGBS? Fly ash ... a byproduct of the ironmaking process, ... The terminology for fly ash and GGBS in concrete ...

Capturing Carbon A new process ... The resulting byproduct can be used as a recycled material in concrete. The processing ... Calera SCMA can replace fly ash ...

Fly AshFor Cement Concrete Resource For High Strength and Durability of Structures at Lower Cost Ash Utilization Division...

Fly Ash Facts for Highway Engineers ... Fly ash concrete is used ... the carbon particles may float to the top during the concrete finishing process and may ...

Researcher tests fly ash for stronger concrete ... OPC or OPC and fly ash as the main binding material and involves slow process of hydration of the OPC/fly ash, ...

This IR is applicable for all concrete mixes utilizing fly ash or natural pozzolans in ... • Reduces green house gas emissions from the processing of raw material

With changes in how electricity is generated, there may be a gradual reduction in available fly ash for use in concrete and other applications. The significant

Fly ash is a byproduct from the combustion of pulverized coal, and is widely used as an ingredient in hydrauliccement concrete. Because it improves many desirable ...

But if fly ash is used also as a filler to replace sand in concrete production, unbeneficiated fly ash with ... the Rhenipal process uses fly ash as an admixture to ...

Fly ash in concrete may also lead to lower early age strengths. ... depending on the coal that was used and the manufacturing process. In lowcalcium fly ash ...

shows in animated form the fly ash processing by DIRK India at their Nashik POZZOCRETE plant

The readymixed concrete producer is increasingly confronted with the challenge of including pozzolans, and specifically fly ash, in marketing and production. T

Fly ash is a byproduct from burning pulverized coal in electric power generating plants. During combustion, mineral impurities in the coal (clay, feldspar, quartz ...

LIFECYCLE ASSESSMENT AND EMISSION FACTOR ... When used in concrete applications, fly ash ... analysis does not include energy associated with fly ash processing ...

Low CO2 Concrete. Stronger, Cleaner ... As with fly ash, processing blast furnace slag into slag cement or slag aggregate eases the burden on our environment in a ...

You can use fly ash in concrete production. ... (FGD) process uses calcium carbonate or calcium oxide to remove sulfur dioxide gas from the coal combustion process.

WhatsApp)

WhatsApp)